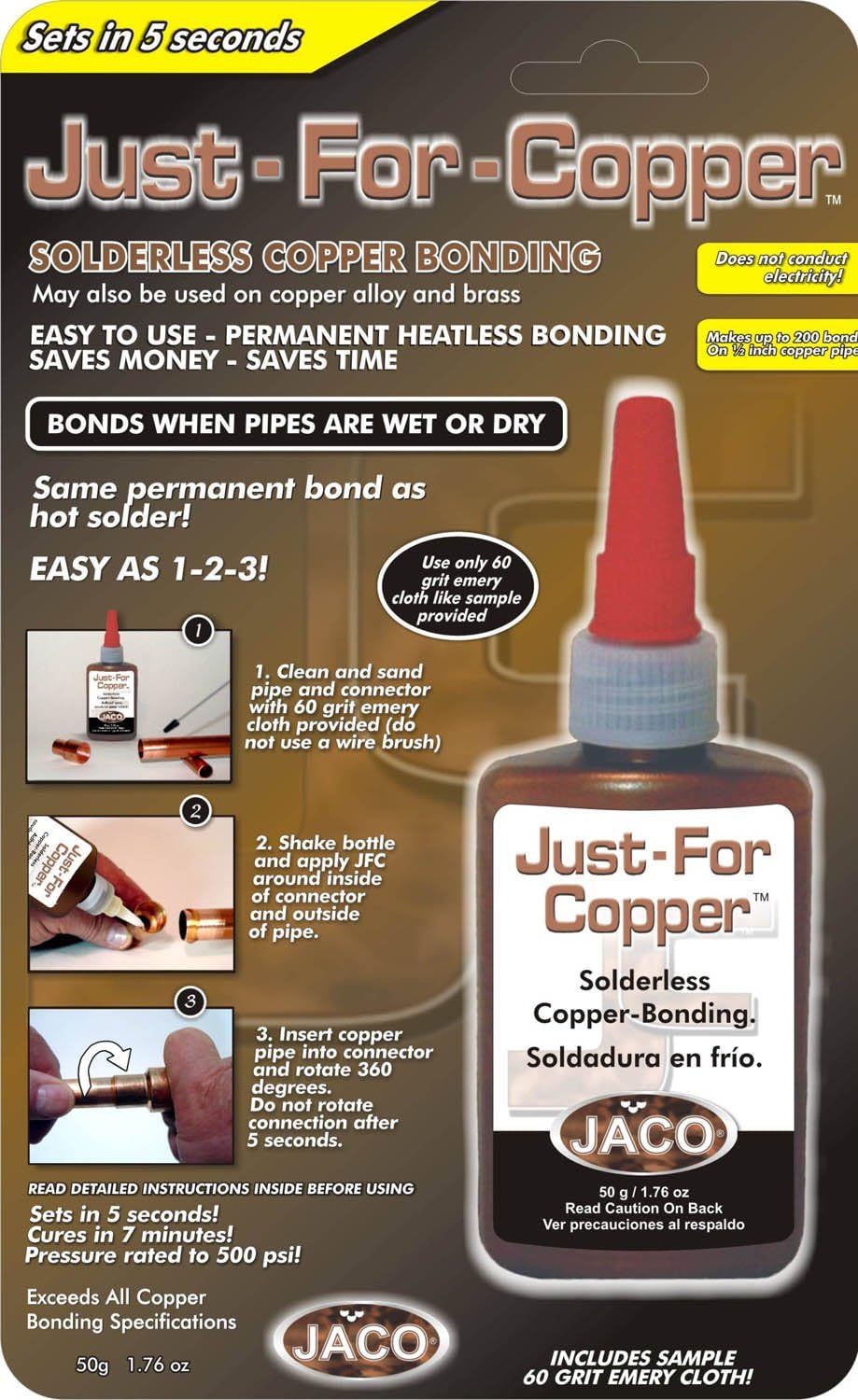

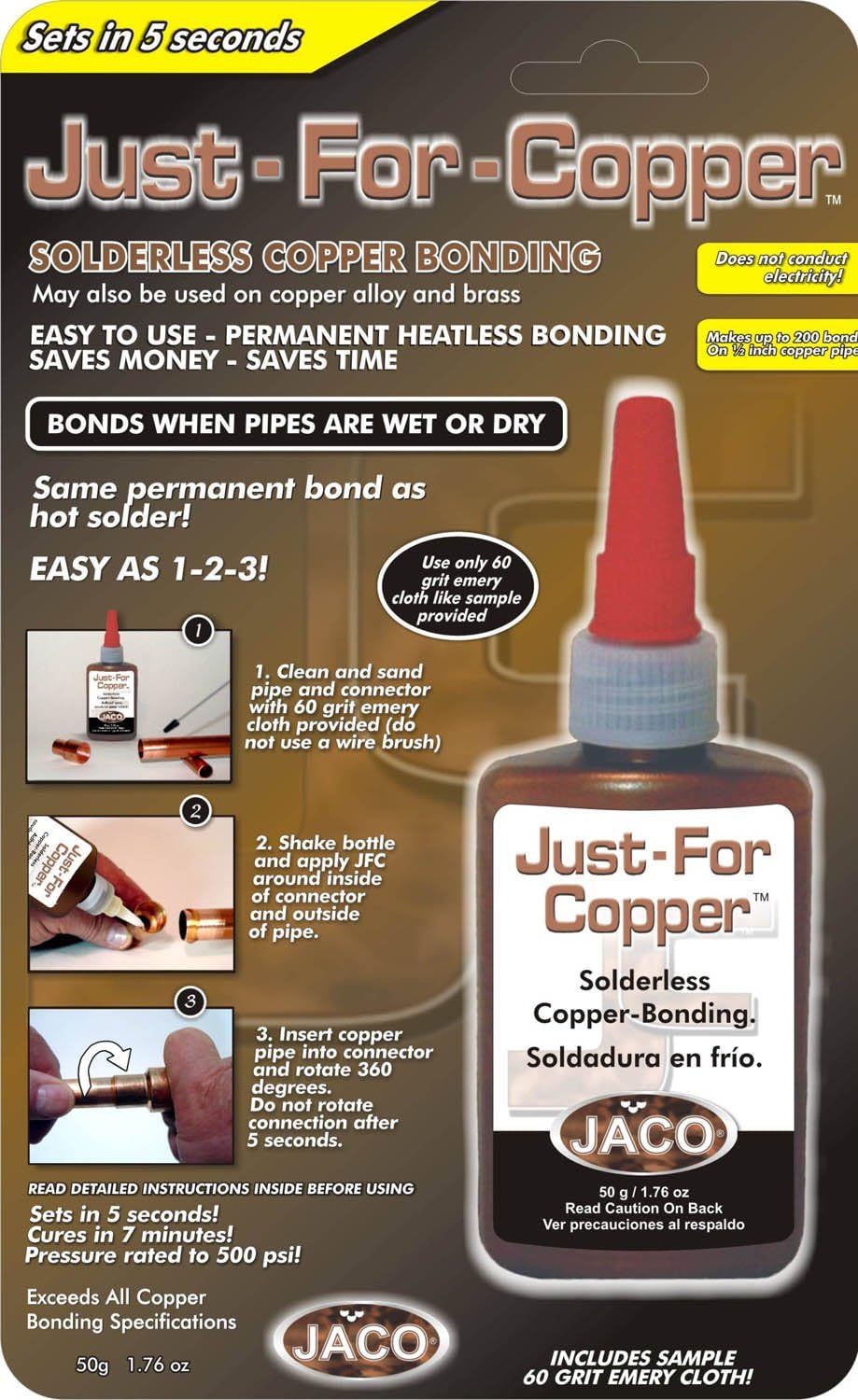

Jackson Industries 1.85 Oz Just For Copper Solderless Copper Bonding JFC050

FREE Shipping

Jackson Industries 1.85 Oz Just For Copper Solderless Copper Bonding JFC050

- Brand: Unbranded

Description

Attach the clamp as soon as you have applied the adhesive and assembled the pieces. You need to keep the clamps in place until the glue is completely cured. If you notice a leak, turn off the water supply, identify the source of the leak, and reapply adhesive to the affected area once it has dried completely. References Meanwhile, in terms of durability, longevity, and material composition, copper wins the competition among all other metal-based pipes. Copper pipes are resistant to both heat and cold, hence a perfect choice for water lines. More so, these can be easily installed above the surface or underground. Grupo Corassa, S. A., owned by the Coba family, formulated the product which later became trademarked as JUST-FOR-COPPER Solderless Copper Bonding. After six years of testing, it was approved by the Government of Colombia and a federal specification was written authorizing only the use of JUST-FOR-COPPER on the copper pipes within the natural gas systems throughout the country of Colombia. The first use of JUST-FOR-COPPER was in 1998. There have been millions of bonds using JUST-FOR-COPPER since that date, and there has never been a failure attributed to JUST-FOR-COPPER.

Preparing the copper pipes involves cutting and measuring the pipes to the appropriate length and cleaning and sanding them to remove any debris or corrosion. This step is crucial in creating a strong bond between the pipes and the adhesive. If the cement is not evenly applied, it can cause gaps between the joints leading to leaks. Reapply cement to the affected area or disassemble the joint and start again. Dust Mask: If you’re working in an area with poor ventilation, it’s recommended that you wear a dust mask to protect your lungs from inhaling any hazardous chemicals found in the adhesive or any dust or debris from preparing the pipes. Next, use a soap solution to cover the joints in the pipe. The goal is to identify any leaks by exposing bubbles that form when the solution meets a leak. You can easily make the soap solution by mixing water and soap detergent in a spray bottle.Yes, sanding the pipes creates a rough surface that allows the adhesive to bond more effectively and creates a better seal. 4. How long does it take for the adhesive to cure? Copper pipes are widely used in plumbing systems due to their durability and resistance to corrosion. However, they are also sensitive to temperature changes and can expand and contract accordingly. This thermal response can exert stress on any adhesive used to secure the pipes. Potential Issues: Soldering involves using heat to melt a metal alloy that is then used to join two pieces of metal together. While this method is popular and effective for copper pipes, it requires a bit more skill and knowledge to use properly. Pipe cement is a more common choice for DIYers.

By being aware of these common problems and following their respective solutions, you can avoid any glitches and ensure a smooth gluing process for your copper pipes. Conclusion A) Metal Water Piping. The metal water piping system shall be bonded as required in (A)(1), (A)(2), or (A)(3) of this section. The bonding jumper(s) shall be installed in accordance with 250.64(A), (B), and (E). The points of attachment of the bonding jumper(s) shall be accessible. One unique characteristic of Gorilla Glue is its expansion during the curing process. This expansion aids in filling gaps and creating a tight bond between surfaces. However, it’s important to apply the glue sparingly and evenly to prevent excessive foaming or bubbling. Proper Application: Instead of relying on Gorilla Glue, it is wise to seek professional assistance when joining copper pipes. Plumbers employ specialized techniques like soldering or brazing, which create strong and permanent bonds capable of withstanding high pressures and temperatures.Internal link: For those who have trouble gluing Traxxas tires, we have an informative guide on how-to-glue-traxxas-tires. Safety Precautions This is definitely the most common method when it comes to attaching PVC or CPVC pipes to copper pipes. Why? Because it does not entail soldering. It means there’s no need for an open flame to attach the pipes. Aside from being a safer way of linking tubes, it’s very easy to install. The curing time will vary depending on the adhesive you use, but typically it takes 1-2 hours for the glue to set and at least 24 hours for it to fully cure. 5. Do I need to use primer before applying the adhesive? This cement is formulated to dry faster than other adhesives, reducing the amount of time that joints need to be held together. However, it is not recommended for use in large diameter pipes or with applications involving high-pressure systems.

You fit ups all have to be straight-true. You can't cram a pipe into a fitting wonky and expect the glue to work. When I hot solder I often 'tweak' things to fit. No doing that with the copper glue. Apart from voiding warranties, there may also be legal implications associated with using non-standard adhesives. If a plumbing disaster occurs as a result of unauthorized adhesive usage, seeking compensation from the manufacturer becomes an uphill battle. They can easily shift blame towards your use of unapproved adhesive, absolving themselves of any responsibility. Challenges for Future Repairs and Maintenance: Cyanoacrylate adhesives are suitable for bonding copper to copper or other materials. Cyanoacrylate glue is the industrial name for “super glue.” It can be used to bond almost anything, including most types of metal, plastic, and organic material. Now, for the final recommendation, we have thread adapters. This method highlights the relevance of utilizing a male plastic end as well as a female metal end. It should not be interchanged because a male adapter may damage the female plastic adapter if pushed very hard.As mentioned earlier, compression fittings are best for long pipe connections. So, if you’re just doing some short connections, probably around 5 meters long, then the most suggested option is push-fit fittings. This method is very easy and perhaps the fastest way to connect PVC and copper pipes. But before you buy push-fit fittings, it’s crucial to know the exact sizes. Moreover, you need to have an idea of the types of push-fits so you can decide the best option. Some of the most common push-fits are elbow fittings, tee, and 1/2″ or 3/4″ couplings. There’s also a push fit with a valve available in the market. Soldering is a remarkable technique used in both plumbing and electronics to securely join metal components together. By melting a metal alloy called solder, a bond is formed between the parts being joined. Typically, solder is a combination of tin and lead, although there are lead-free alternatives available. Step 4: Repeat the process for all the remaining pipes and fittings, gradually putting your system together.

- Fruugo ID: 258392218-563234582

- EAN: 764486781913

-

Sold by: Fruugo